January 2024

A new Patent GB2615349 Hydrodynamic Method for Processing Natural Graphite was granted. This technology is instrumental in the production of highly conductive composites and anodic graphite for lithium batteries. This patent underscores GS's commitment to pioneering advancements in the field of energy storage and material science.

November 2023

A crucial meeting took place between the GS team and representatives from the University of Warwick and WMG. The focus of the discussion was the collaborative efforts in developing and testing advanced materials for lithium batteries.

October 2023

GS launched a cutting-edge machine designed for the production of anodic graphite and highly conductive composites.

March 2023

Graphene Star and Rustins are launching G Insulate at the FutureBuild 2023 taking place at ExCel London on 7-9 March.

G Insulate is a primer which has been scientifically manufactured to transform walls, ceilings and floors into energy saving structures, resulting in reduced carbon emissions, savings on energy bills and taking a step towards net zero.

#Graphene Star is taking a stand to reduce energy consumption

February 2023

We are pleased to announce that Graphene Star has been awarded a grant by Innovate UK as part of the UK Research and Innovation’s Faraday Battery Challenge to participate in developing thin and lightweight current collector for lithium-ion battery (LIB).

LIB batteries are one of the heaviest and most expensive components in a battery EV. This pioneering project aims to develop a lightweight and low-cost polymer current collector to replace the aluminium and copper foil current collectors used in LIBs. This is estimated to reduce the weight of the automotive battery pack by nearly 10% whilst increasing the battery’s charge and power density.

https://www.ukri.org/news/delivering-the-future-of-battery-technology//

January 2023

At Graphene Star we are thrilled to be featured in NPL’s case studies publication this week. National Physical Laboratory validated the effectiveness of shielding and thermal paints produced by Graphene Star in collaboration with Rustins. This is another positive step forward for the company in building consumers’ trust in our products.

https://www.npl.co.uk/case-studies/high-temperature-shielding-thermal-paints

DECEMBER 2022

The start of production of a new acrylic paint G Insulate at the Rustins factory. The paint is intended for use as a primer for walls and ceilings to stabilize the temperature inside any premises during heating or air conditioning with energy savings of up to 21%. The paint is made on the basis of GS's graphite composite.

NOVEMBER 2022

Successful completion of tests of a new acrylic coating based on graphite composite manufactured by GS in real buildings. The new coating, used as a primer, allows you to save energy when heating any premises up to 21% due to the high reflective properties of the coating in the infrared range.

April 2022

Successful tests of GS conductive coatings were carried out within the framework of the NPL M4R program. The results of this testing confirmed the high stability of GS conductive coatings in vacuum, at various ambient humidity and at frequencies from 1 Hz to 100 kHz.

February 2022

An MOU has been signed between Graphene Star and AMD, which will allow both companies to combine efforts for the development and production of graphene coatings of a new generation.

February 2022

Graphene Star has applied for a new patent, which describes the Green Graphite technology.

July 2021

As part of the M4R program from NPL, a program of tests of various graphite precursors that are used for graphene production at Graphene Star was carried out.

June 2021

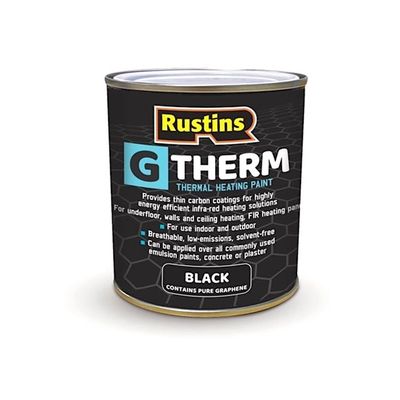

Rustins and Graphene Star have signed an agreement on the production and promotion of innovative products G Shield and G Therm.

May 2021

CEO of Graphene Star Marina Starkova in Nixene Publishing: Contributing Editor Debbie Nelson posed a set of questions to the CEO and Director of Graphene Star Ltd.

April 2021

Within the framework of cooperation between Graphene Star and the University of Warwick, successful tests of Graphene Star's graphene anode composites in lithium cells were carried out.

March 2021

The first batch of G Therm paint was produced at Rustins in London. The paint is designed for easy and fast creation of heated coatings on any surfaces.

February 2021

The first batch of G Shield paint was produced at Rustins in London. The paint is designed for highly effective shielding of electromagnetic radiation in a wide frequency range.

October 2020

As part of the M4R NPL program, unique tests of the shielding properties of Graphene Star graphene coatings have been completed. The test results demonstrate the high efficiency of shielding graphene coatings in a wide range of electromagnetic radiation with attenuation up to -70 decibels.

November 2019

Graphene Star company has patented its original method of graphene production. This method of graphene production is unique, highly efficient and absolutely environmentally friendly.

DECEMBER 2017

The production of graphite powder and aqueous graphene paste has been started at the production facilities of Graphene Star. The company's graphene products have many potential applications in various industries.

Copyright © 2024 www.graphene-star.com -all rights reserved

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.